Center for Nanotechnology

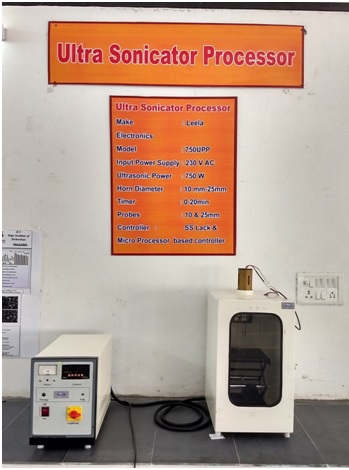

ULTRASONIC PROBE SONICATOR

- Ultrasonic Generator to produced high-Frequency Electrical Energy operating at a frequency of 20KHZ and Ultrasonic Power of 120W

- S.S. Velocity Horn fitted with PZT Crystals (Transducer Elements).

The Velocity Horn assembly converts the electrical high-frequency energy fed from the Ultrasonic generator to mechanical vibrations at the rate of applied electrical frequency. The amplitude of these mechanical vibrations is magnified by this Velocity Horn. This Velocity Horn is used for the processing application.

| Make | Leela Electronics |

| Model | 750UPP |

| In Put Power Supply | 230 V AC |

| Ultrasonic Power | 750 W |

| Horn Dia | 10 mm- 25 mm |

| Timer | 0-20 min |

| Probes | 10 & 25 mm |

Features of Ultrasonic Probe Processor :

- Low transducer losses permit maximum cleaning action

- Modular generator for easier modification / Servicing

- Rugged and easy to clean stainless steel housing

- Extensively protected electronics circuits for longer and safe operation

- Frequency 22 + 3 KHz.

- Input voltage range of 170AC-270 AC.50 Hz

2. MINIMUM QUANTITY LUBRICATOR

This CNC mister oves from machine to machine without production delays. Hand-carry this versatile lubricator from one scheduled cutting or machining equipment to the next. A heavy-duty magnet lets you install it with minimal downtime.

Oil mist lubrication system roduces a continuous output of precisely metered lubricants. Air-driven, positive-displacement pumps precisely meter each drop of lubricant at .03 cc/stroke. The 100-million cycle pulse generator allows for automatic, infinite repeat cycling of the metering pump. This ensures that a continuous, external film of lubricant is applied to the tool-work interface.

Lets operator easily control atomization of the spray by adjusting air, pulse per minute and liquid metering.

Adjusts output from 4-200 injection cycles per minute with 0.1 to 3.0 drops of lubricant per cycle. A durable, vented 16 oz. reservoir on the CNC mister holds more than 14,400 drops of lubricant.

Dispenses any highly refined lubricant including Unist’s high-efficiency Coolube® from the oil mist lubrication system’s durable, 16 oz. (0.5 L) vented reservoir.

The CNC mister combines lubricant and air in the patented Co-Axial Nozzle tip. The oil mist lubrication system keeps atomization and distribution of the liquid consistent regardless of the hose length. Plastic 12 in. nozzle is coupled with 5 ft. Co-Axial hose. A heavy-duty magnetic base at the hose/nozzle connection of the oil mist lubrication system makes it easier to relocate and position the nozzle at the friction points.

| Make | UNIST (USA) |

| Model | Coollubricator JR |

| Fluid adjustment | |

| Air adjustment | |

| Built-in manual on/off valve | |

| Portable, 5’ hose, 12” plastic nozzle | |

| Reliable, .03 cc/stroke Unist pump | |

| Proven, 100 million cycle pulse generator Tough, vented 16 oz (.5 L) reservoir | |

| Heavy-duty magnetic base |

3. HOT AIR OVEN

| Make | Cassia Siamia Technologies |

| Capacity | 100 ltrs |

| Inner chamber dimension | 50 cms (L) * 50 cms (W) * 40 cms (H) |

| Interior | Stainless Steel Finish |

| Grade | SS304 |

| Exterior | Galvanized Iron with Powder Coated |

4. MUFFLE FURNACE

| Make | Cassia Siamia Technologies |

| Size | 15 * 15 * 30 cms |

| M.O.C | GI Powder Coated |

5. DOUBLE PIPE HEAT EXCHANGER

6. MAGNETIC STIRRER

Specifications of magnetic stirrer:

| Make | RemiElektrotechnik Limited |

| Speed Control Range | 15 to 1500 RPM |

| Max. Stirring Volume (water) | 800ml |

| Stir Bar Length | 25mm |

| Working Surface Material | Stainless Steel |

| Temperature Range | 5 – 40 |

| Voltage [V] | 220 – 240 |

Standard Features:

- PMDC(Permanent Magnet DC) motor for higher torque even at low speeds

- Better speed regulation even with small volume and low speeds

- Accurate step less speed control maintains excellent speed stability.

- Digital Speed Indicator for displaying of stirring speed

- Totally enclosed unit

- Designed for use even in corrosive atmosphere

7. CHEMICALS

Papers Published

- VM Krishna, “Heat transfer enhancement by using ZnO water nanofluid in a concentric tube heat exchanger under forced convection”, Internal Journal of Innovations in engineering and technology, 7(4), 177-184, 2016, ISSN: 2319-1058.

- VM Krishna, “Experimental investigation of heat transfer enhancement by using Al2O3- water nanofluid in a concentric tube heat exchanger”, Internal Journal of Mechanical Engineering and Technology, 7(6), 449-458, 2016, ISSN:0976-6340.

- VM Krishna, “Enhancement of heat transfer in forced convection by using Fe2O3- water nanofluid in a concentric tube heat exchanger”, Internal Journal of Engineering and Technology, 6(5), 102-107, 2016, ISSN: 2277-3754.

- VM Krishna, “Heat transfer enhancement by using CuO – water nanofluid in a concentric tube heat exchanger- An experimental study”, Internal Journal of Mechanical Engineering, 6(1), 11-20, 2017, ISSN: 2319-2259.

- V Murali Krishna, M Sandeep Kumar “Numerical analysis of forced convective heat transfer of nanofluids in a microchannel for cooling electronic equipment”, Materials Today: Proceedings (Scopus), 17,295-302,2019, 10.1016/j.matpr. 2019.06.433.

- V Murali Krishna, M Sandeep Kumar “Experimental Investigation on Performance of Hybrid PCM‟s on Addition of Nano Particles in Thermal Energy Storage”, Materials Today: Proceedings (Scopus), 17,271-276, 2019, 10.1016/j.matpr. 2019.06.430.

- Senthil Kumar P, V Murali Krishna “Effect of TiiB2 on the Corrosion Resistance Behavior of In Situ Al Composites”, Materials Today: Proceedings (Scopus), International Journal of Metal casting (Springer), 14,84-91, 2019, 10.1007/s40962 -019-00330-3, 0.71 IF. (SCI).

M Sandeep Kumar “Fabrication and parametric optimization of SiO2-BN gel cast ceramic composites using response surface methodology”, Materials Today: Proceedings (Scopus), 18, 2298- 2307, 2019. https://doi.org/10.1016/j.matpr.2019.07.012.

M Sandeep Kumar, V Murali Krishna, Varun.A “Investigation on the influence of Hybrid Biodegradable Nanofluids (CuO-ZnO) on Surface Roughness in Turning AISI 1018 Steel”, Materials Today: Proceedings (Scopus), 24, 1570-1576, 2020. https://doi.org/10.1016/j.matpr.2020.04.477

M Sandeep Kumar, V Murali Krishna “An Investigation on Turning AISI 1018 Steel with Hybrid Biodegradable Nanofluid/MQL Incorporated with Combinations of CuO-Al2O3 Nanoparticles”, Materials Today: Proceedings (Scopus), 24, 1577-1584, 2020. https://doi.org/10.1016/j.matpr.2020.04.478.

M Sandeep Kumar “Investigation on Influence of Hybrid Nanofluid MQL on Surface Roughness in Turning Inconel-718”, Advances in Applied Mechanical Engineering (LNME Lecture Note), 1137-1144, 202011. https://doi.org/10 .1007/978-981-15-1201-8_120

V Murali Krishna, M Sandeep Kumar, Senthil Kumar P “Numerical investigation of heat transfer and pressure drop for cooling of the microchannel heat sink using MWCNT-CuO-Water hybrid nanofluid with different mixture ratio”, Materials Today: Proceedings (Scopus), 42, 969-974, 2021. ISSN 2214-7853. 10.1016/j.matpr.2020.11.935

2018 – 2019

Title: Design and analysis of hydraulic impeller using polymer Nanocomposite

| Roll No | Name of the student | Name of the Guide |

| 15211A0323 | D Mounika | Mr. Vijay Kiran |

| 15211A0302 | Ch. Yaswanth Ram | |

| 15211A0343 | K Divyasri |

Title: Enhancement of Heat Transfer in Micro Channel Heat Sink Using Hybrid Al2O3 Water Nanofluid and PCM Suspension for Cooling Of Micro Electronic Devices

| Roll No | Name of the student | Name of the Guide |

| 15211A03B4 | V Santosh Varma | Dr. V. Murali Krishna |

| 15211A03B7 | Y Uday Kumar | |

| 15211A03A8 | T Murali Krishna |

Title: Machining studies on AISI 1018 using nanofluids with various combinations of CuO- Al2O3 particles and comparing it with different lubricating conditions

| Roll No | Name of the student | Name of the Guide |

| 15211A0389 | Perka Sai Sumiran | Mr. T Mahesh |

| 15211A0373 | Nandala Akhil Teja | |

| 15211A0374 | Neeradi Ajay Kumar |

2017 – 2018

Title: Thermal Energy Storage Using hybrid Nano Phase Change Materials

| Roll No | Name of the student | Name of the Guide |

| 14211A0377 | Akula Vamshidhar | Dr. M Sandeep Kumar |

| 14211A0382 | Kota Nandini | |

| 13211A0371 | Sai Sindesh |

Title: Thermal Energy Storage Using Hybrid Nano Phase Change Materials

| Roll No | Name of the student | Name of the Guide |

| 14211A0320 | T Soumya | Dr. M Sandeep Kumar |

| 14211A0319 | G Vandhana | |

| 13211A0358 | S Sai Kumar |

Title: Experimental Investigation On Performance Of Hybrid Pcms On Addition Of Nano In Thermal Energy Storage: Heat Exchanger

| Roll No | Name of the student | Name of the Guide |

| 14211A0374 | Jaggayyagari Ravali | Dr. M Sandeep Kumar |

| 14211A0370 | G. Sri Lalitha Chidrupi | |

| 13211A0381 | Kudurla Akhila |

Title: Performance analysis of domestic refrigerator using nano refrigerant

| Roll No | Name of the student | Name of the Guide |

| 14211A0309 | T Indra karan | Mr. Koppala Rama Siva Reddy |

| 14211A0335 | Marri Manasa | |

| 14211A0356 | K Karthik |

Title: Modeling and FD analysis of an automobile radiator by using Hybrid Nanofluids

| Roll No | Name of the student | Name of the Guide |

| 14211A0305 | Naveen Reddy | Dr. V Murali Krishna |

| 14211A0323 | U Sravan Kumar | |

| 14211A0353 | N Nithin Kumar |

Title: Heat Transfer enhancement in micro channels using nanofluids for cooling of electronic equipment

| Roll No | Name of the student | Name of the Guide |

| 14211A0376 | M Rohita Sai | Dr. V Murali Krishna |

| 14211A03A7 | G Vinay Kumar | |

| 14211A03A8 | K Akhilesh |

Title: Theoretical study on enhancement of heat transfer by using Al2O3-H2O and CuO- H2O Nano fluids in a concentric tube heat exchanger

| Roll No | Name of the student | Name of the Guide |

| 14211A0334 | S Prasoon | Dr. V Murali Krishna |

| 14211A0341 | Nelige Harish | |

| 15211A0307 | E. Manikanth |

Title: Testing the fatigue behavior of hybrid polymer nanocomposite

| Roll No | Name of the student | Name of the Guide |

| 14211A0310 | K sadvini Reddy | Mr. B. Vijay Kiran |

| 14211A0330 | K Suresh | |

| 14211A0336 | B Naveena |

Title: Testing the tensile flexure and hardness properties on silica core shell rubber nanoparticles in E-Glass fibre reinforced polymer composites

| Roll No | Name of the student | Name of the Guide |

| 14211A0380 | V Soumya | Mr. B. Vijay Kiran |

| 14211A0383 | M Mallikarjunayya | |

| 14401A0314 | B Sushma |

2016-17

Title: Enhancement of heat transfer using Al2O3 and CuO hybrid nanofluid in a concentric heat exchanger

| Roll No | Name of the Student | Name of the Guide |

| 13211A0395 | Sneha B | Dr. V. Murali Krishna |

| 14215A0316 | Rangagouni Vishnu Goud | |

| 14215A0319 | Rupavath Shankar |

Title: Experimental investigation of influence of hybrid nanofluids (Cuo-ZnO) as cutting fluids in turning of AISI 1018

| Roll No | Name of the Student | Name of the Guide |

| 13211A0396 | Sowjanya M | Mr. M. Sandeep Kumar |

| 13211A03A2 | Srikanth Reddy | |

| 13211A03B7 | Vijaya Laxmi Pujari |

Title: Machining studies on AISI 1018 using nanofluids with various combinations of CuO- Al2O3 particles and comparing it with different lubricating conditions

| Roll No | Name of the Student | Name of the Guide |

| 13211A0388 | Shaik Jan Saida | Mr. M. Sandeep Kumar |

| 13211A0399 | Sri Lakshmi | |

| 13211A03A8 | Surya Teja Verma I |

Title: Fabrication and testing of Graphene-oxide nano particles in E-glass fiber reinforced polymer composites

| Roll No | Name of the Student | Name of the Guide |

| 13211A0305 | Akhil Kumar A | Mr. B. Vijay Kiran |

| 13211A0351 | Pranay Kumar kattela | |

| 13211A0303 | N Ajay Kumar |

Title: Fracture and fatigue behavior of epoxy-TiO2 Nano composites reinforced with E-glass

| Roll No | Name of the Student | Name of the Guide |

| 13211A0340 | Nagamohan Kalyanam | Mr. B. Vijay Kiran |

| 14215A0311 | Pyata Shiva Kumar | |

| 14215A0312 | Bandugu Vamshi |

Title: Effect of Aluminum oxide Nano particles on Hemp fiber composites

| Roll No | Name of the Student | Name of the Guide |

| 13211A0306 | Amul sargoad | Mr. Koppala Rama Siva Reddy |

| 13211A0308 | Arun kumar | |

| 13211A0341 | Narendar Pilli |

2015-16

Title: Enhancement of Convective Heat Transfer with Fiber Nanofluid in a concentric tube heat exchanger

| Roll No | Name of the Student | Name of the Guide |

| 12211A0329 | Kanaka Maha laxmi P R | Dr. V. Murali Krishna |

| 12211A0302 | Aditya Dutt Avaru | |

| 12211A0347 | Pallavi Palle | |

| 12211A0304 | Akhila Podupati |

2014-15

Title: Preparation of CuO and Al2O3 nanoparticles and heat transfer enchancement by using CuO and Al2O3 nanofluids in a concentric tube heat exchanger

| Roll No | Name of the Student | Name of the Guide |

| 11211A0357 | Vineeth kumar Gungi | Dr. V. Murali Krishna |

| 11211A0318 | Kalyan kumar | |

| 11211A0337 | Saikiran M |

Title: Preparation of ZnO and Fe2O3 nanoparticles and heat transfer enchancement by using ZnO and Fe2O3 nanofluids in a concentric tube heat exchanger

| Roll No | Name of the Student | Name of the Guide |

| 11211A0319 | Krishna Novle | Dr. V. Murali Krishna |

| 11211A0353 | Varun Teja Adepu | |

| 11211A0310 | Keruba Ramesh |