The Chemical Engineering Process Intensification and Research Lab is a specialized facility that focuses on process intensification techniques and research in the field of chemical engineering. Process intensification aims to enhance the efficiency, productivity, and sustainability of chemical processes by optimizing their design, operation, and equipment. The lab conducts experiments and investigations into various process intensification methods, such as microreactors, structured catalysts, membrane separations, and hybrid systems, to name a few. Through cutting-edge research and innovation, the lab seeks to develop new and improved processes that offer reduced energy consumption, minimized waste generation, and increased product yields. The findings and knowledge generated in this lab are instrumental in driving advancements in chemical engineering and promoting sustainable and environmentally-friendly practices in the chemical industry.

Objectives:

The objectives of a Chemical Engineering Process Intensification and Research Lab can include:

- Development of Innovative Processes: To design, develop, and optimize novel chemical processes that are more efficient, cost-effective, and sustainable than conventional methods. This involves exploring new technologies, equipment, and techniques to intensify the processes.

- Resource Efficiency: To reduce the consumption of energy, raw materials, and utilities in chemical processes. Process intensification aims to achieve higher product yields and reduced waste generation, contributing to resource conservation.

- Environmental Sustainability: To promote environmentally friendly practices by minimizing the environmental impact of chemical processes. This may involve the design of cleaner and greener processes that produce fewer emissions and pollutants.

- Scale-up and Commercialization: To assess the feasibility of scaling up intensified processes from laboratory-scale to industrial-scale production. The lab aims to bridge the gap between research and industrial application.

- Multi-disciplinary Research: To encourage collaboration between different fields of engineering, chemistry, and materials science, fostering cross-disciplinary research to address complex challenges in process intensification.

- Advanced Characterization Techniques: To employ state-of-the-art analytical and characterization tools to study the behavior of materials and processes under different conditions, providing valuable insights for process optimization.

- Safety and Reliability: To ensure that intensified processes meet high safety standards and are reliable for continuous operation, preventing accidents and downtime in industrial settings.

- Waste Minimization and Recycling: To explore ways to minimize waste generation and increase the recycling of by-products or unused materials, reducing the environmental impact of chemical processes.

- Continuous Process Improvement: To continuously improve and optimize existing chemical processes by incorporating new findings and methodologies from research conducted in the lab.

- Education and Training: To provide a platform for students, researchers, and industry professionals to gain knowledge and skills related to process intensification, fostering a workforce capable of implementing advanced and sustainable chemical engineering practices.

Aim:

The aim of the Process Intensification and Research Lab is to optimize and enhance chemical and industrial processes through innovative technologies and methodologies, leading to improved efficiency and sustainability.

Vision:

The vision of the Chemical Engineering Process Intensification and Research Lab is to revolutionize the field of chemical engineering by continuously pushing the boundaries of process intensification, developing groundbreaking solutions that enhance efficiency, sustainability, and safety in chemical processes, and ultimately contributing to a greener and more prosperous world.

Mission:

The mission of the Chemical Engineering Process Intensification and Research Lab is to develop and apply innovative technologies and methodologies to optimize chemical processes, minimizing waste generation and energy consumption while maximizing productivity and product quality. Through collaboration and knowledge dissemination, we aim to drive transformative changes in the chemical industry, benefitting society and the environment.

Research Facilities

Outcomes

Publications:

- 2023:

- Unified correlations for the prediction of the slip velocity, characteristic velocity, flooding throughput and flooding slip velocity in a pulsed disc and doughnut extraction column, Chemical Engineering Communications

- Advances on value-added application of waste soot materials, Materials Today: Proceedings

- Enhancement of wood-plastic composite properties in presence of recycled vehicular soot as a carbon source material: Sustainable management approach, Process Safety and Environmental Protection

- Preparation of polypropylene co-polymer (PPCP) based composites with improved properties in presence of MWCNT and MAgPP fillers, Materials Today: Proceedings

- Production of biodiesel: kinetics and reusability studies of the Mg-Al hydrotalcite catalyst using Jatropha oil , Reaction Chemistry and Engineering

- Potential efficacy of a fruit waste – Manila tamarind seed powder for the adsorption of hazardous dyes from aqueous solution: Batch studies, Materials Today: Proceedings

- Application of emulsion nanofluid membrane for the removal of methylene blue dye: stability study, Chemical Papers

- Effect of concentration and heat inputs on thermal conductvity of SiC/oil nanofluids, Engineering Research Express

- Photocatalytic decolourization of Rhodamine-B dye by visible light active ZIF-8/BiFeO3 composite, Environmental Science and Pollution Research

- Restoration and Deblurring the Images by Using Blind Convolution Method, Lecture Notes in Networks and Systems

- Intensification of PCM Thermal Conductivity With Nanomaterials For Thermal Energy Storage Applications, Journal of Chemical Technology and Metallurgy

- 2022:

- Valorization of Hazardous Materials along with Biomass for Green Energy Generation and Environmental Sustainability through Pyrolysis, Journal of Chemistry

- Exhibition of Dielectric Property Based on Soil Class and Moisture Presence for Bengaluru District, Advances in Materials Science and Engineering

- Biosorption of dyes onto low cost adsorbent in a fixed bed column, Materials Today: Proceedings

- Modeling and technoeconomic analysis of biogas production from waste food, Biofuels and Bioenergy: A Techno-Economic Approach

- Preparation of polypropylene co-polymer (PPCP) based composites with improved properties in presence of MWCNT and MAgPP fillers, Materials Today: Proceedings

- Sustainable use of recycled soot (carbon black) for the cleaner production of value-added products: A compendium, Chemical Engineering Journal Advances

- Liquid phase hydrogenation of phenol catalyzed by silica supported palladium to yield cyclohexanone, Materials Today: Proceedings

- Use of additives to improve bonding strength of the adhesive prepared from used polymer: Sustainable management approach, Materials Today: Proceedings

- Preparation and characterization of green composites based on expanded polystyrene waste and biomass: Sustainable management approach, Materials Today: Proceedings

- An Introduction to Bioenergy, Biofuel, and Bio Refining Environmental Science and Engineering

- Simulation of a Steady-State Continuous Catalytic Reactive Distillation Column by Using a Multiscale Capillary Model, Chemical Engineering and Technology

- Comparison of Experimental and Simulations for Esterification Process for Recovery of Acetic Acid by Reactive Distillation, Environmental Science and Engineering

- Kinetic Studies for the Esterification of Propionic Acid with 1-Butanol Process with Ionic Resin Catalyst, Environmental Science and Engineering

- Water Removal from an Ethanol-Water Mixture at Azeotropic Condition by Adsorption Technique, Adsorption Science and Technology

- Experimental and simulation studies of a continuous reactive distillation for an esterification process, International Journal of Chemical Reactor Engineering

- Preparation of Ti Material Supported SBA-15 Functionalized with Sulfonic Acid Environmental Friendly Catalyst: Application for Esterification Process, Journal of Nanomaterials

- Fundamentals of advanced oxidation processes (AOPs) for wastewater treatment: Challenges and opportunities, Novel Approaches towards Wastewater Treatment and Resource Recovery Technologies

- Highly Photoactive Titanium Dioxide Supported Platinum Catalyst: Synthesis Using Cleaner Ultrasound Approach, Catalysts

- Nickel Oxide Nanoparticles: A Brief Review of Their Synthesis, Characterization, and Applications, Chemical Engineering and Technology

- Optimization of multiple parameters for adsorption of arsenic (III) from aqueous solution using Psidium guajava leaf powder, Water Science and Technology

- 2021:

- Kinetic studies on esterification of acetic acid with isopropyl alcohol in presence of novel solid catalyst, International Journal of Chemical Reactor Engineering

- A simulated annealing optimization algorithm based nonlinear model predictive control strategy with application, Evolving Systems

- Natural convection heat transfer using water-based nanofluid in a shell and helical coil heat exchanger, Chemical Papers

- Studies on development of adhesive material from post-consumer (waste) expanded polystyrene: a two-edged sword approach, Process Safety and Environmental Protection

- Laboratory scale bioreactor studies on the production of l-asparaginase using Rhizopus microsporus IBBL-2 and Trichosporonasahii IBBLA1, Biocatalysis and Agricultural Biotechnology

- Prediction of solids outlet moisture content in a continuous wall heated fluidized bed dryer for uniform and binary solid mixtures, World Review of Science, Technology and Sustainable Development

- Textile industry Wastewater Treatment by cavitation combined with Fenton and Ceramic Nanofiltration, Chemical Engineering and Processing

- Heat Management in Supersonic/Hypersonic Vehicles Using Endothermic Fuel: Perspective and Challenges, ACS Omega

- Potential Applications of Post-Consumer Vinyl Flex Banner (PCVFB) Materials: Sustainable Management Approach, International Journal of Sustainable Engineering

- Use of Additives to Improve Bonding Strength of the Adhesive Prepared from Used Polymer: Sustainable Management Approach, Materials Today: Proceedings

- Advances in metal-based vanadate compound photocatalysts: synthesis, properties and applications, Synthesis and Sintering

- 2020:

- Metabolic pathway analysis and dynamic macroscopic model development for lovastatin production by Monascuspurpureus using metabolic foot printing concept, Biochemical Engineering Journal

- Kinetic modelling and simulation studies for the esterification process with Amberlyst 16 resin, Indian Journal of Chemistry-Section A

- Scientific and Engineering Aspects of potential applications of post-consumer (waste) Expanded Polystyrene: A Review, Process Safety and Environmental Protection,

- Enhancing adsorption capacity of nano-adsorbents via surface modification: A review, South African Journal of Chemical Engineering

- Multiobjective Pareto optimisation of pharmaceutical product formulation using radial basis function network and non-dominated sorting differential evolution, Int. J. Biomedical Engineering and Technology

- Sonochemical approach for synthesis of zinc oxide-poly methyl methacrylate hybrid nanoparticles and its application in corrosion inhibition, International Journal of Engineering &Technology

- Self-polymerization reaction of cyclohexanone: Kinetics and thermodynamics, Materials Today: Proceedings

- 2019:

- In pursuit of the best artificial neural network configuration for the prediction of output parameters of corrugated plate heat exchanger, Fuel

- Development of an Activity Based Kinetic Model for an Esterification Process with Indion180 Catalyst, International Journal of Chemical Reactor Engineering

- Data on conceptual design and simulation of reactive distillation process, Data in Brief.

- 2018:

- Identification of better gene expression data for mosquito species classification using radial basis function network methodology, The Open Bioinformatics Journal

- Determination of optimum conditions in a continuous wall heated fluidized bed dryer, International Journal of Pure and Applied Mathematics

- Data on acetic acid–methanol–methyl acetate–water mixture analysised by dual packed column Gas Chromatography, Data in Brief

- Removal of reactive yellow (RY) AZO dye using activated carbon synthesized from fire stick wood, International Journal of Engineering &Technology

- Critical review of abatement of ammonia from wastewater, Journal of Molecular Liquids

- Kinetic Study of Ethyl Hezanoate Synthesis Using Surface Coated Lipase from Candida Rugosa, Iranian Journal of Chemistry and Chemical Engineering

- Optimization studies on biosynthesis of citric acid by one-factor-at-a-time, Chemistry and Chemical Technology

- Kinetic Studies for the Esterification Process with Ionic Resin Catalyst: Optimization using Response Surface Methodology, International Journal of Engineering and Technology

- Mathematical Model of Radial Flow Reactor for Naphtha Hydrodesulphurization, International Journal of Engineering and Advanced Technology (IJEAT)

- Dynamic simulation of heterogeneous catalysis at particle scale to estimate the kinetic parameters for the pore diffusion model, Bulletin of Chemical Reaction Engineering and Catalysis

- 2017:

- Catalytic Reactive Distillation for the Esterification Process: Experimental and Simulation Chemical and Biochemical Engineering Quarterly,

- Lipase Catalyzed transesterification of ethyl butyrate synthesis, Journal of food Science and Technology

- Effect of distribution on performance of a continuous fluidized bed dryer, Heat Mass Transfer

- Kinetic behaviour of esterification of acetic acidwith methanol over solid acid catalysts, Austin ChemEng

- Synthesis of Fe Doped Titania Nanoparticles for the Removal of Hexavalent Chromium from Synthetic Cr(VI) Solution, International Journal of Engineering Technology Science and Research

UG Projects

2019 – 2023 Batch:

- Biosorption of Methylene blue using Natural biosorbents: Column Studies

- Extraction of pigment from micro organisms – Experimental and optimization studies

- Synthesis and characterization of Hydrogels

- Preparation and Characterization of Wood Plastic Composites using waste plastic and corn husk

- Production of biodiesel from waste vegetable oil

- Effect of waste soot on the properties of the wood-plastic composites

- Extraction and characterization of Biopolymer from Fish Scales

- Oil Extraction From Delonix Regia Seeds

- Green synthesis of TiO2 nanoparticles for photocatalytic degradation of Methylene Blue

- study on saponification reaction in microreactor

- Heat transfer studies in Corrugated channels

2018 – 2022 Batch

- CFD Modeling of a fixed bed biofilm reactor

- Biosoprtion of methyelne blue using low cost adsorbent

- Synthesis of Pectin-TiO2 particles and its application in removal of Rhodamine B dye

- Studies on Preparation and Characterization of Cost-effective and Eco-friendly Composites

- Adsorption of Methylene Blue from an aqueous solution by using chemically activated porous Carbon

- Rheological Study of various brands of toothpastes

- Intensification of dye wastewater treatment using advanced oxidation processes

- Green Synthesis of TiO2 nanoparticles using Citrus Limon leaf extract for dye degradation

- Study of pool boiling and critical heat flux enhancement in nanofluids

- Production of Bioethanol from cellulosic material with Saccharomyces Cervisiae

2017-2021 Batch:

- Studies on Preparation and Characterization of Green Composites Prepared from Waste Polymer and Biomass Materials

- Production Of Acetone From Iso-Propanol

2016-2020 Batch:

- Enhancement of thermocol adhesive properties using different cross linking agents

- Biosorption of Methylene blue using custard apple leaves

- Synthesis of cellulose hydrogel

- Kinetics and Modeling of Palmarosa Essential Oil

- Green Synthesis of silver nanoparticles using orange peel extract

- Evaluation of portable indoor air purifiers in removal of gaseous pollutants (SO2, NO2 and CO2)

- Kinetic studies on esterification of n-propanol with n-propionic acid

- Mini Hydrogen Electrolyser from vehicular fuel blending

- Metformin Production API

2015-2019 Batch:

- Dehydration of isopropyl alcohol by pervaporation using mixed matrix membrane

- Design of extraction process of rice bran oil

- Conversion of rice husk to levulinic acid:biomass value addition

- Production of cellulose acetate from agro-based waste namely rice husk, sugarcane bagasse and banana stem

- Extraction of silica from rice husk ash and its applications

- Study on sewage water treatment plant

- Removal of copper from aqueous solution using citric acid modified rice husk

- Biosorption of metal ions from waste water using azadirachta india (neem leaf) and phyllanthus emblica (amla leaf)

Simulation Projects:

2019-2023 Batch

- Simulation of Bio-Hydrogen Production from Sugarcane Bagasse using ASPEN

- Multimodel Statistical Design Analysis For Production Of Bioethanol From Fungal Species

2018 – 2022 Batch

- CFD Modeling of a fixed bed biofilm reactor

- ASPEN Plus based modeling of CO 2 sequestration

- Modeling and simulation of reactive distillation for esterification of acetic acid with ethanol process

2017 – 2021 Batch:

- Neural network based modeling of anaerobic fixed bed biofilm reactor treating tannery wastewater

- Modeling and Simulation Of A Packed Bed Reactor

- Three Phase Fluidized Bed- Hydrodynamic Studies Using CFD Simulation

- Studies On Simulation Of Shell and Tube Heat Exchanger With Different Parameters Using DWSIM

- Manufacture Of 2-Propanol using DWSIM

- Production of Hydrogen Peroxide using DWSIM

- Numerical Studies on Heat Transfer characteristics of Double Pipe and Helical Coil Heat Exchange

- Simulation Studies On Esterification Of Acetic Acid and Methanol In A Plug Flow Reactor

- Optimization and Evaluation of L- Asparaginase activity in production process using Design Expert software

- Simulation and Investment Analysis Of Cumene Production Plant

2016 – 2020 Batch

- Heat Transfer Studies on Helical Coil Heat Exchanger Using CFD

- Development of ANN model and optimization for microwave rying kinetics of Bitter Gourd

- CFD analysis of lfow of non-newtonian fluids through constricted micro channel

2015-2019 Batch

- Neural network based modeling of flow of oil in water emulsion through constricted micro capillary

- A performance study of conventional heat exchangers using CHEMCAD

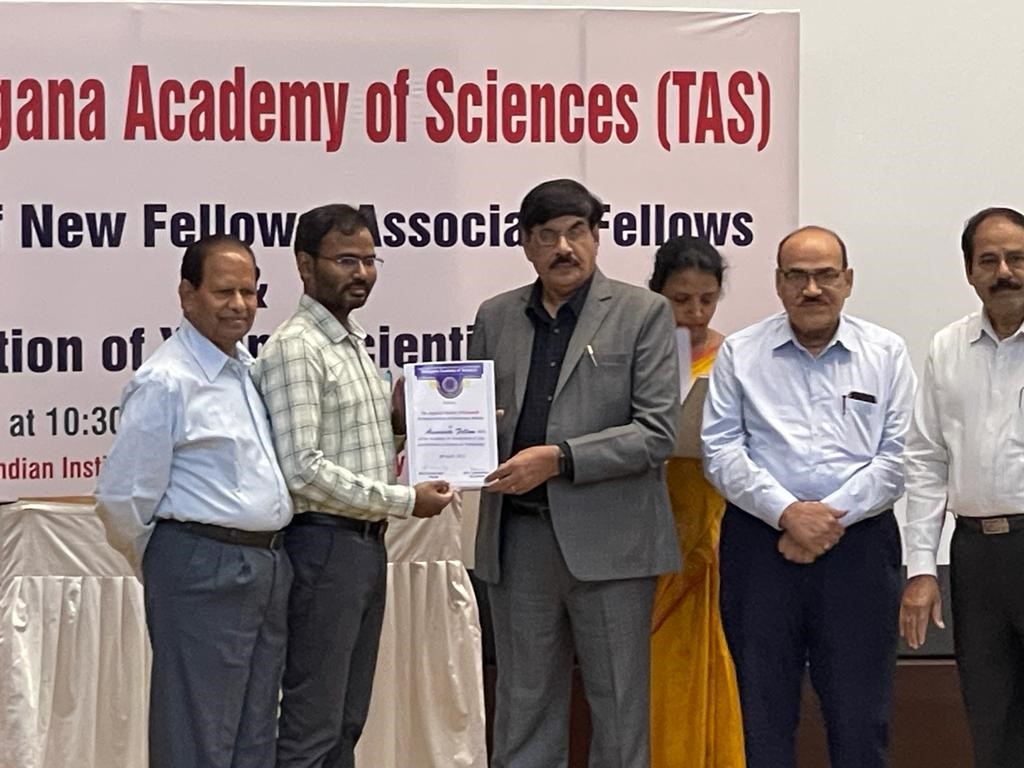

Awards and Recognitions