TVS Haritha Techserve

TVS HARITA TECHSERV Centre of Excellence in Advanced CAD/CAM,CAE,PLM & Digital Manufacturing

Department of Mechanical Engineering has started Centre of Excellence “TVS HARITA TECHSERV in Advanced CAD/CAM, CAE, PLM & Digital Manufacturing” in collaboration with HARITA TECHSERV with a vision to build the knowledge gap between design and application of Technology.

The Centre is inaugurated on 15th October 2016 by our chairman Sri. K. V. Vishnu Raju garu and Shankarnarayanan, Chief operating officer HARITA TECHSERV.

The centre would act as a conduit for technology’s journey, facilitates the integration of industry, inculcate best practices knowledge sharing and value creation.

- Faculty training by HARITA TECHSERV training Experts in current trends of industry to stay ahead of the curve.

- Student Training in high end software packages.

- Conduct Campus placement drive for recruiting Engineers.

- Promote collaborative research on Advanced CAD/CAE software.

- Provide internship to students.

- Live projects, product design and research activities by faculty and students

- Conduct Technical workshops ,enable students to learn and practice practical examples from time to time.

- Depute technical experts to give technical seminars.

|  |

| |

Major Hardware / Software:

| S.No | Hardware / Software | Quantity |

| 1. | HP DL 160 Gen6 Server (64 GB RAM, 1.5TB Hard disk) | 1 |

| 2. | HP Z400 workstation (16 GB RAM, 1TB Hard disk) | 30 |

| 3. | HP PRO 3330 Desktop PC | 36 |

| 4. | Rc AllTech UPS | 11KVA + 6KVA |

| 5. | Siemens CAD Bundle (NX 10.0) | 20 |

| 6. | ENOVIA PLM | 10 |

| 7. | DELMIA V6(Advanced Digital Manufacturing) | 5 |

| 8. | Siemens CAM | 5 |

| 9. | CATIA V6 | 10 |

| 10. | ANSYS | 25 |

| 11. | ANSYS Academic Research Mechanical and CFD | 1 |

The center provides perfect platform for training industry ready students in the field of design and analysis software, promoting research activities and helping them to get better placements in companies like HARITA TECH SERV, CYIENT, TCS etc.,

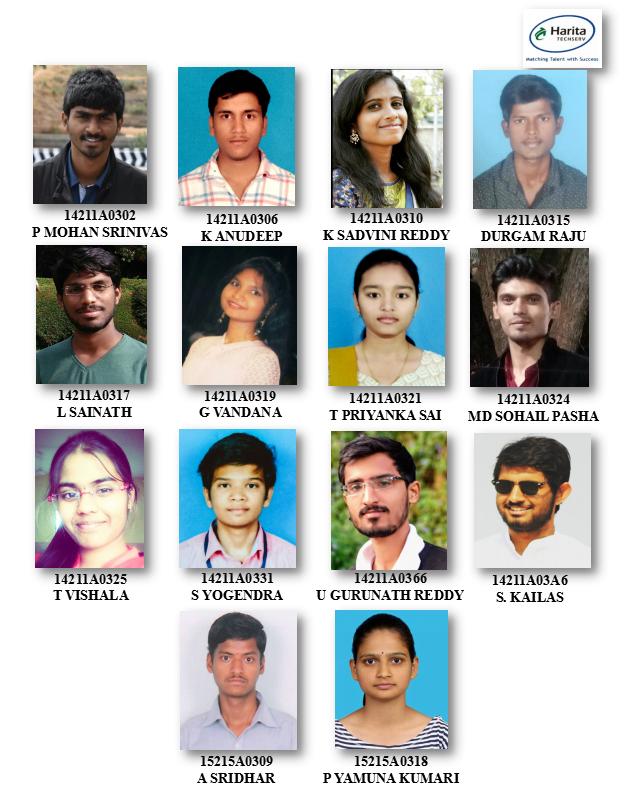

Placements: The following students are benefited in Placement and Internships.

2013-17 Batch Placements

CYIENT selects | Haritha TECHSERV |

2014-18 Batch Placements

CYIENT selects | HARITA TECHSERV selects |

1. Title: Faculty Training Program on CATIA V6

Duration: 01-11-2016 to 12-11-2016

No of Faculty/Students benefited: 5 faculties

|  |  |

2. Title: 3 weeks Student Training Program on CATIA V6

Duration: 06-03-2017 to 26-03-2017

No of Faculty/Students benefited: 50 students

|  |  |

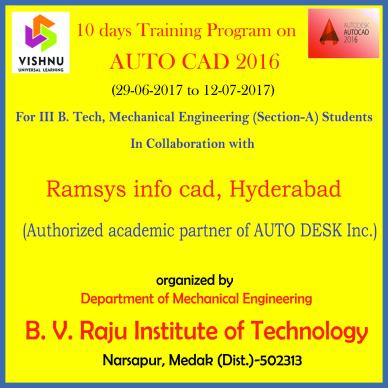

3. Title: 10 days Training Program on AUTO CAD 2016

Duration: 29-06-2017 to 12-07-2017

No of Faculty/Students benefited: 63 students

|  |

|  |

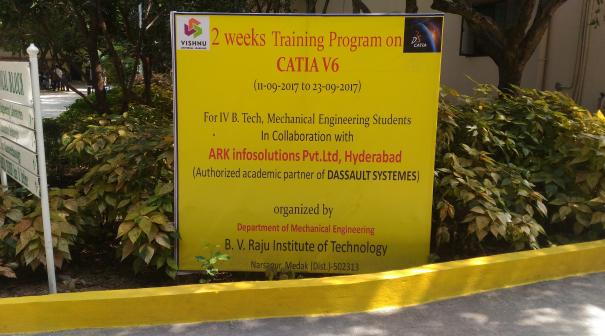

4. Title: 2 weeks Student Training Program on CATIA V6

Duration: 11-09-2017 to 23-09-2017

No of Faculty/Students benefited: 58

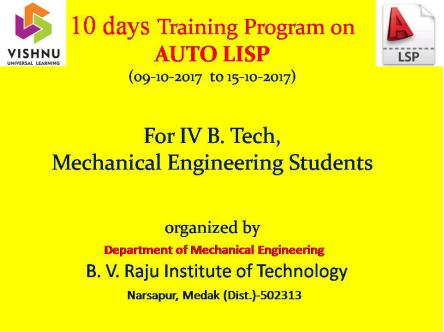

5. Title: 10 days Training Program on AUTO LISP

Duration: 09-10-2017 to 15-10-2017

No of Faculty/Students benefited: 23 students

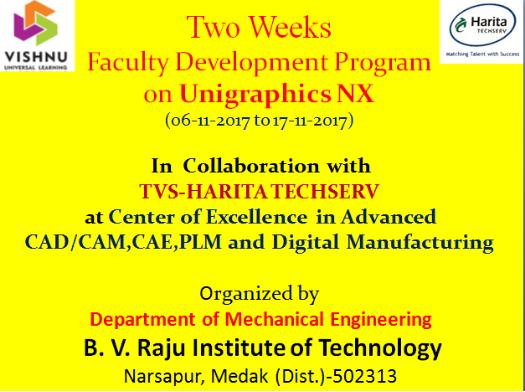

6. Title: 2 weeks Faculty Development Program on UNIGRAPHICS NX 10.0

Duration: 06-11-2017 to 17-11-2017

No of Faculty/Students benefited: 9 faculties

|  |

|  |

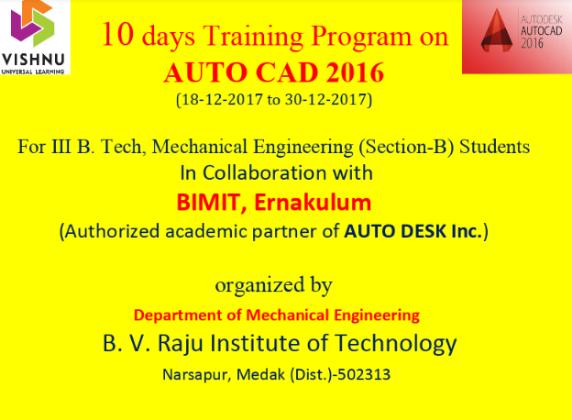

7. Title: 10 days Training Program on AUTO CAD 2016

Duration: 18-12-2017 to 30-12-2017

No of Faculty/Students benefited: 50 students

|  |

| |

8. Title: One day Seminar onAutodesk Fusion 360

Duration: 29-01-2018

No of Faculty/Students benefited: 50 students

|  |

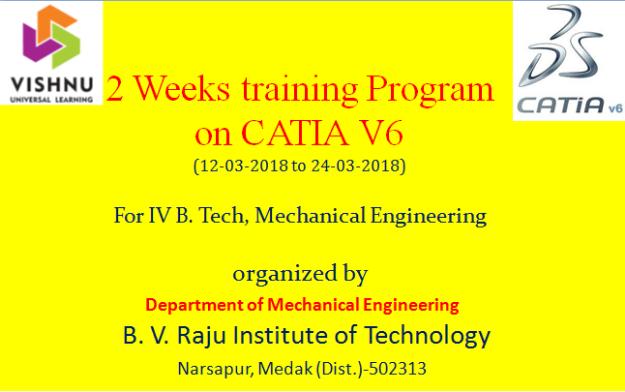

9. Title: 2 weeks Student Training Program on CATIA V6

Duration: 12-03-2018 to 24-03-2018

No of Faculty/Students benefited: 50 students

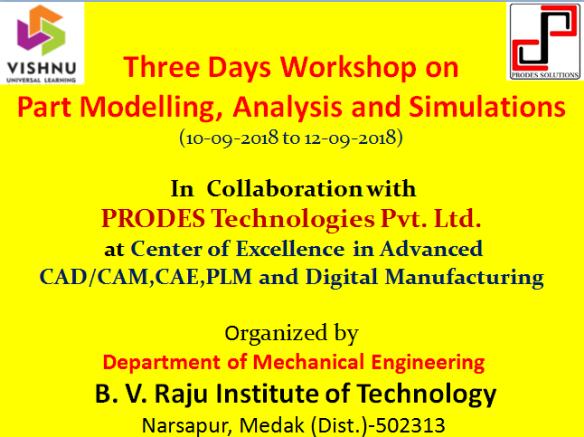

10. Title: Three Days Workshop on Part Modelling, Analysis and Simulations

Duration: 10-09-2018 to 12-09-2018

No of Faculty/Students benefited: 60 students

|  |

| |

The Mechanical Engineers design, build, test, and then improvise their solution before the actual production begins with innovation playing a key role.

The students have complete access to the advanced softwares like CATIA V6, UNI Graphics NX 10.0, ENOVIA PLM, DELMIA V6, Siemens CAM etc, which have been installed in the TVS HARITA TECHSERV Centre of Excellence. The students have been utilizing the available softwares to carry out their academic major and minor projects as well as real time projects.

2013-17 Batch:

| S.No | Name of the Project | Names of the student | Hall ticket Number |

| 1 | CFD analysis of fin arrays in IC engine | Anand Varma M | 13211A0307 |

| Kanaka Sai Rahul V | 13211A0332 | ||

| Naresh Bhukya | 13211A0342 | ||

| 2 | Design and analysis of guide rods of an automobile head restraint | Suhas Rao T | 13211A03A6 |

| Venkatapatiraju B | 13211A03B6 | ||

| 3 | Design and Analysis of Crane Hook for different load conditions | Kumar Swamy Reddy S | 13211A0338 |

| Rohith Deshmukh | 13211A0358 | ||

| Sadhashiva Reddy K | 13211A0359 | ||

| 4 | Design and analysis of Roof holding structures used in Underground Mining | Goshika Lahari | 13211A0321 |

| Hima Bindu Kadali | 13211A0324 | ||

| 5 | Design and analysis of connecting rod of Internal combustion engine using 6110A and 7075-T6 Aluminum | Bharath Kumar Thalari | 13211A0311 |

| Sagar Patil P | 13211A0360 | ||

| Begari Mary | 14215A0305 | ||

| 6 | Design and analysis of diesel engine exhaust poppet valve by using composite materials | Chandra Shekhar Reddy | 13211A0316 |

| Adduri Gowtham | 14215A0301 | ||

| Aillapaka Paulu | 14215A0310 | ||

| 7 | Design and Analysis of front under run protection device | Devika Bhukya | 13211A0318 |

| Pranavi Kondakindi | 13211A0350 | ||

| Polisetti Nagendra Babu | 14215A0308 | ||

| 8 | Design and analysis of heavy load vehicle ladder chassis using ANSYS | Bharath Ram H | 13211A0312 |

| Deepika Dappu | 13211A0317 | ||

| Naveen Kumar Puppala | 13211A0343 | ||

| 9 | Design and analysis of progress press tool | Santhosh Sachin M | 13211A0380 |

| Sushanth Kulkarni | 13211A03B0 | ||

| Vishnu Vardhan Sattu | 13211A03B9 | ||

| 10 | Design and fabrication of automatic white board cleaning system | Devavath Suresh | 14215A0314 |

| Singitham Pandu Ranga | 14215A0318 | ||

| Muthyala Rakesh | 14215A0321 | ||

| 11 | Design and fabrication of lever operated pesticide sprayer using bicycle | Sai Charan S | 13211A0363 |

| Sai Teja Reddychittela | 13211A0374 | ||

| Saiteja Ch | 13211A0375 | ||

| D Shivashankar Goud | 14215A0320 | ||

| 12 | Modeling and Analysis of Hydraulic die ejector | Satish Kumar Goud B | 13211A0383 |

| Satish Reddy Ganji | 13211A0384 | ||

| Vijaykrishna Reddy A | 13211A03B8 | ||

| 13 | Optimization of burst pressure of LPG cylinder in an Automobile using ANSYS | Ajay Kumar Goud N | 13211A0303 |

| Akash Naik Banoth | 13211A0304 | ||

| Kishore Kumar Pawar | 13211A0335 |

2014-18 Batch:

S.No | Name of the Project | Names of the students | Hall ticket No. |

1 | Design and Analysis of Alloy wheel | SATIVADA YOGENDRA | 14211A0331 |

KATROTH DEVENDER | 14211A0313 | ||

K RAGHU BHARAT VARMA | 14211A0351 | ||

2 | Design and Analysis of two wheeler shock absorber coil spring | BALAGAM SUKUMAR | 14211A0312 |

GOOTAM TONY PRASHANTH | 15215A0305 | ||

CH NAGA KALYAN BABU | 14211A0343 | ||

3 | Design of Heat recovery boiler | POSIMSETTY MOHAN SRINIVAS | 14211A0302 |

D. BANU TEJA REDDY | 14211A0344 | ||

THANDU BENHUR ROHITH | 14211A0329 | ||

4 | Design and analysis of loop heat pipe | TALLA PRIYANKKA SAI | 14211A0321 |

SANKOJU SATISH KUMAR | 14211A0339 | ||

V. NAGAVENKATA SAI ANUDEEP | 14211A0345 | ||

5 | Modeling and CFD analysis of an Automobile radiator by using hybrid nano fluids | NAVEEN KUMAR YADAV | 14211A0305 |

UPPADA SRAVAN KUMAR | 14211A0323 | ||

NAGULA NITHIN KUMAR | 14211A0353 | ||

6 | Design and analysis of steering knuckle for weight reduction | K SAI CHANDRAKANTH | 15215A0303 |

RONANKI DRONA CHARYULU | 14211A0318 | ||

JVS SHAHSHANK | 14211A0359 | ||

7 | Thermal analysis of an automobile radiator with and without louvered fins | BOLLEPALLI BHASKAR RAJU | 14211A0338 |

SINGIREDDY NIKHIL REDDY | 14211A0303 | ||

K.V. SAI KISHORE | 14211A0348 | ||

8 | Design and Analysis of pump impeller made of ABS plastic | R R VENKATA MANIKARAN | 15215A0315 |

BADRAMRAJU SAI NATH | 14211A0373 | ||

R NAVANEETHA | 14211A0398 | ||

9 | Modeling and analysis of IC Engine piston using different materials | P YAMUNA KUMARI | 15215A0318 |

MALOTH NIRMALA | 15215A0324 | ||

BATTULA SUPRIYA | 14211A0399 | ||

10 | Design, motion analysis and fabrication of four way hacksaw | MOHD TALEEB | 14211A0388 |

KOTHAGADI SOUMYA | 14211A0389 | ||

SHAIK SHOEB AHMED | 14211A03A1 | ||

11 | Design and analysis of engine block made with ZAMAK material | GURUMAL SAI PRANAV | 14211A0365 |

RUDRARAJU TEJESH VARMA | 14211A03B8 | ||

R. SAI PRASAD | 14211A03B3 | ||

12 | Design and CFD analysis of centrifugal pump impeller with splitter blades | L MAHESHWAR REDDY | 15215A0320 |

N SANDEEP REDDY | 15215A0319 | ||

CHELIME MANIDEEP | 14211A03B7 | ||

13 | Design and analysis of cam shaft for multi cylinder engine | USKANELLY GURUNATH REDDY | 14211A0366 |

DASARI NAGA SURESH | 14211A0397 | ||

14 | Vibration Analysis of Railway track using ANSYS | P YAJNESH NAVEENCHANDRA | 14211A03C0 |

S. KAILAS | 14211A03A6 | ||

PULAGUM SAI SANKETH REDDY | 14211A03B9 | ||

15 | Design and fabrication of scissor lift for ascending of handicapped person | U VENKATA PRASHANTH | 14211A0364 |

A VISHNU VARDHAN RAO | 14211A0363 | ||

ANDOLE SHARATH CHANDRA | 14211A03B4 |

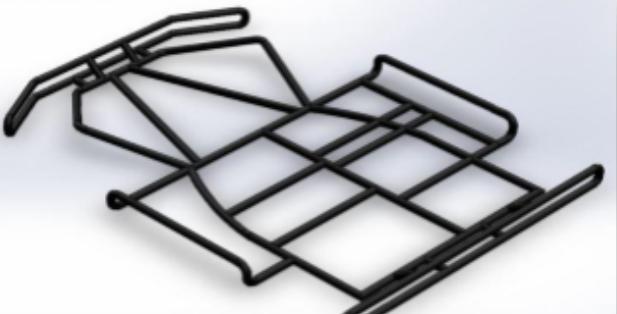

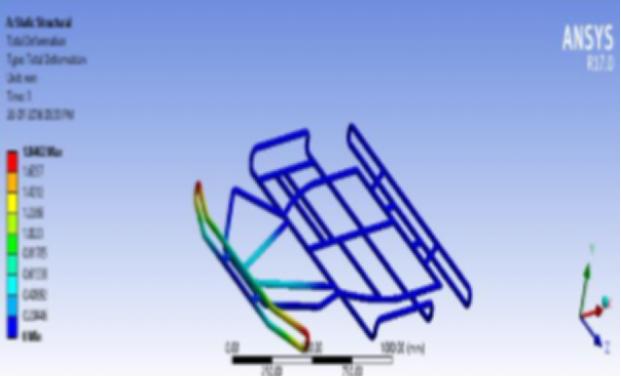

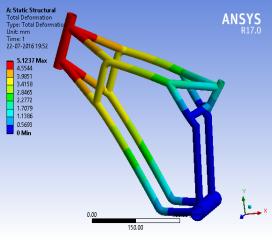

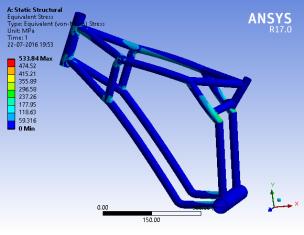

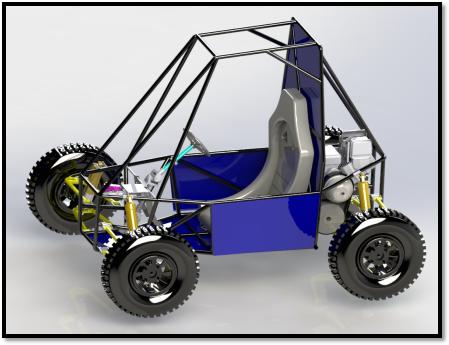

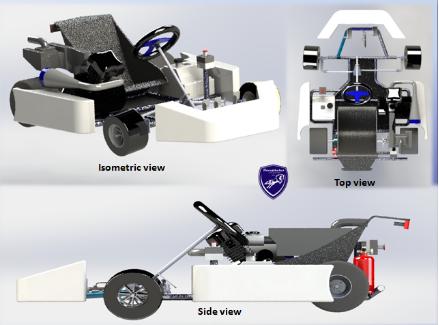

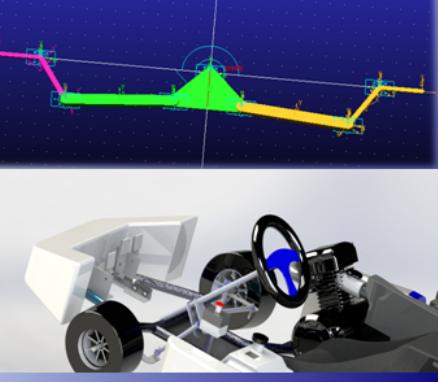

The students of Mechanical Engineering have been participating in various National level Design competitions, Automobile events, Aero design challenge etc., across the country where they Design, Analyze and fabricate various Models, Gokarts, ATV’s, E-bikes etc., by utilizing the advanced Design, Analysis and PLM softwares which are available in the TVS HARITA TECHSERV centre of excellence.

Participated in National Kart Racing Championship held at Kolhapur 2016.

|  |

|  |

Participated in Vishnu E-Moto Championship held at Bhimavaram from 2016

|  |

|  |

| |

Participated in Vishnu Karting Championship held at Bhimavaram from Jan 27-30, 2017.

|  |

|  |

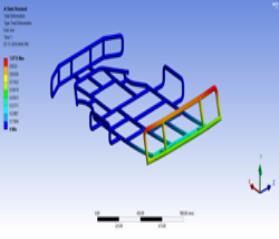

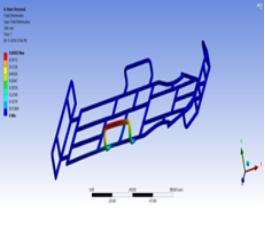

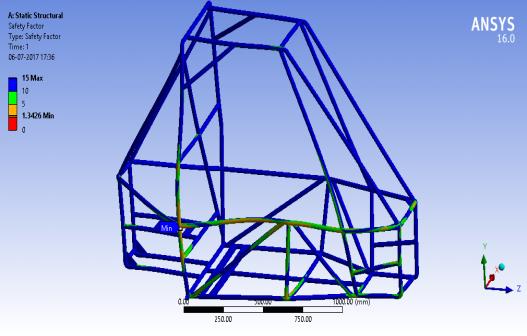

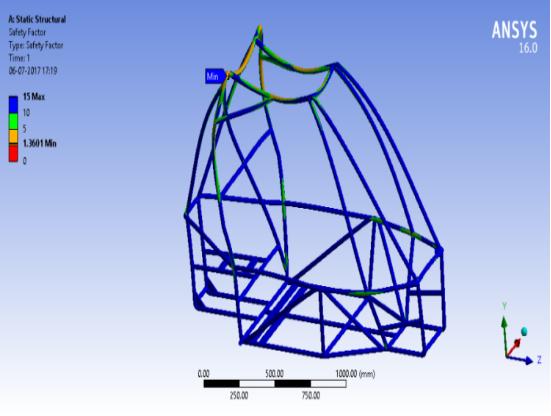

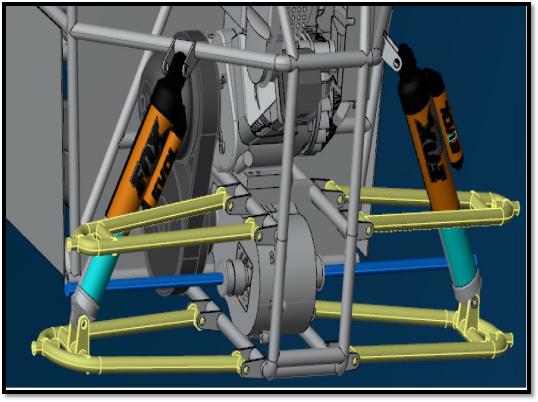

Participated in National Level Virtual BAJA SAEINDIA 2018(All-terrain Vehicle) held at Bangalore 2016.

|  |

|  |

| |

Participated in National Level AUTO INDIA RACING CHAMPIONSHIP 2017 held at Pune, Maharashtra, 16th to 19th March 2017.

The Modeling and different analysies work done by the students.

|  |

| |

About Haritatechserv

Harita has evolved from the TVS stable and nurtures the core values of the group. In today’s swift changing business environment, companies find it a daunting task to hire, train and retain quality talent, especially qualified technical resources and specialists with domain expertise. We make it easier for clients by providing flexible, on-demand engineering design solutions and the right sourcing for their dynamic requirements.

Our extensive screening processes enable clients to get superior quality resources with domain skill sets that are of high caliber. With our on-site services, we manage your workforce, maximize productivity and provide you tangible RoI, thus living true to our commitment towards every client’s success.

About Center for Automotive Electronics (CAE)

BVRIT Narsapur started Center for Auto Electronics (CAE) in collaboration with Harita techserv with a vision to build the knowledge gap between design and application of Technology.

- Centre for Automotive Electronics is providing the training to the students of Electrical and Electronics Engineering, Electronics and communication Engineering and Mechanical Engineering.

- The center will be led by the Department of EEE, Dr. K. Rayudu.

Sl.No | Faculty Coordinators | Department |

1 | Mr. Y Vijay Reddy | EEE |

2 | Mr R Anirudh Reddy Mr. M Hussain | ECE |

3 | Mr R. Muthalagu | Mechanical |

Benefits to the students:

- Students will have exposure to the current model vehicle Electrical / Electronic architecture.

- Students will have an understanding of the basic building of vehicle E&E systems such as sensors, Actuators & bus system

- Students will learn skills required by the Automotive industry

- Students will be placed in the Electrical vehicle/Automobile industry.

- Students will be “Ready to Employ” as entry level – Design/Auto Electronics.

- Students will have hands on experience in latest tools, which makes students ready to work in any automotive industry.

- Students will gain knowledge in latest technologies and the architecture of sensors and actuators used in automobile industry.

Course Outcomes

Trained Engineers who undergo the program will be able to

- Understand the electronics in Automobiles

- Hands on Experience in CAN Communication and ECU Networking

- Exposure to UDS- Vehicle Diagnostics

- Hands on Experience in CAN Tools- ECU Simulation, Automotive- V&V

- Basic Level hands on in Autosar and ADAS

Module-1 Training Outcomes

- Students will have exposure in the current model vehicle’s Electrical/Electronic architecture

- Students will have an understanding of the basic building of vehicle E&E systems such as sensors, Actuators & bus system

- Hands-on experience with CAN tools which makes them ready to work on any automotive project which involves CAN communication

- ECU embedded system architecture & programming

Module-2 Training Outcomes

- Students would be exposed to advanced automotive topics such as ADAS/ Functional Safety & Cybersecurity

- Understand the ECUS which are highly associated with ADAS/FS/ Cybersecurity features

- Creating vehicle level requirements for ADAS/FS/Cybersecurity features

- Understanding the various technologies involved in V&V methods for ADAS/ FS/ Cybersecurity features

30 IV B.Tech Mechanical Engineering and Electrical and Electronics Engineering students have gone through the training on from

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.