Electrical engineering is concerned with the study and use of electricity, electronics, and electromagnetic, and is mostly concerned with large-scale electrical systems, power transmission, and motor control. Electrical engineering has progressed from Edison and Tesla’s basic electric circuits through Bode and Nyquist’s rocket science to the intricacy of IC, satellites, and communication networks. The demand for electrical energy in our country is rapidly expanding, necessitating the need for increased power generation. As a result, electrical engineers’ roles are becoming increasingly crucial in today’s world.

Department of EEE have the resources to give aspiring engineers with the training and expertise they need to make a significant contribution in this field. Initially, the curriculum offers students with a broad foundation upon which they may build their particular expertise. Professional engineers with a strong working understanding of analogue, digital, and power electronics, electrical machines, and power systems, with an emphasis on applications, have been produced in recent years. With well-equipped laboratories and a staff of skilled and motivated teaching members, the Department has an outstanding infrastructure to establish a pleasant academic atmosphere in which to offer quality education.

The department features a well-developed Research & Development facilities that is led by experienced academics. It also has a sufficient number of technically qualified and self-motivated personnel. The Department has strong ties with industry, and one of the benefits for our students is that they are in high demand, not only in the local market but also globally.

Special Laboratories:

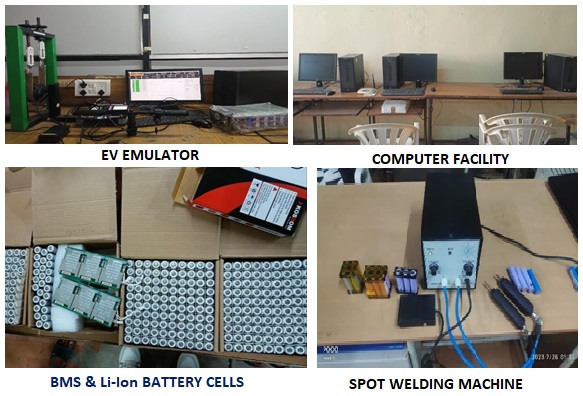

The purpose of the EV Lab is to bring awareness to green technology inside the campus and for an Adaptive learning experience for the Young Engineers.

The students design the Li-ion battery packs, analyze the performance of EV motors for various load conditions, Analyzed the charging and discharging characteristics of LFP Battery packs, etc.

The lab is equipped with EV Emulator System Assembly, Spot welding Machine, IR Machine, Clamp meter etc.,

About:

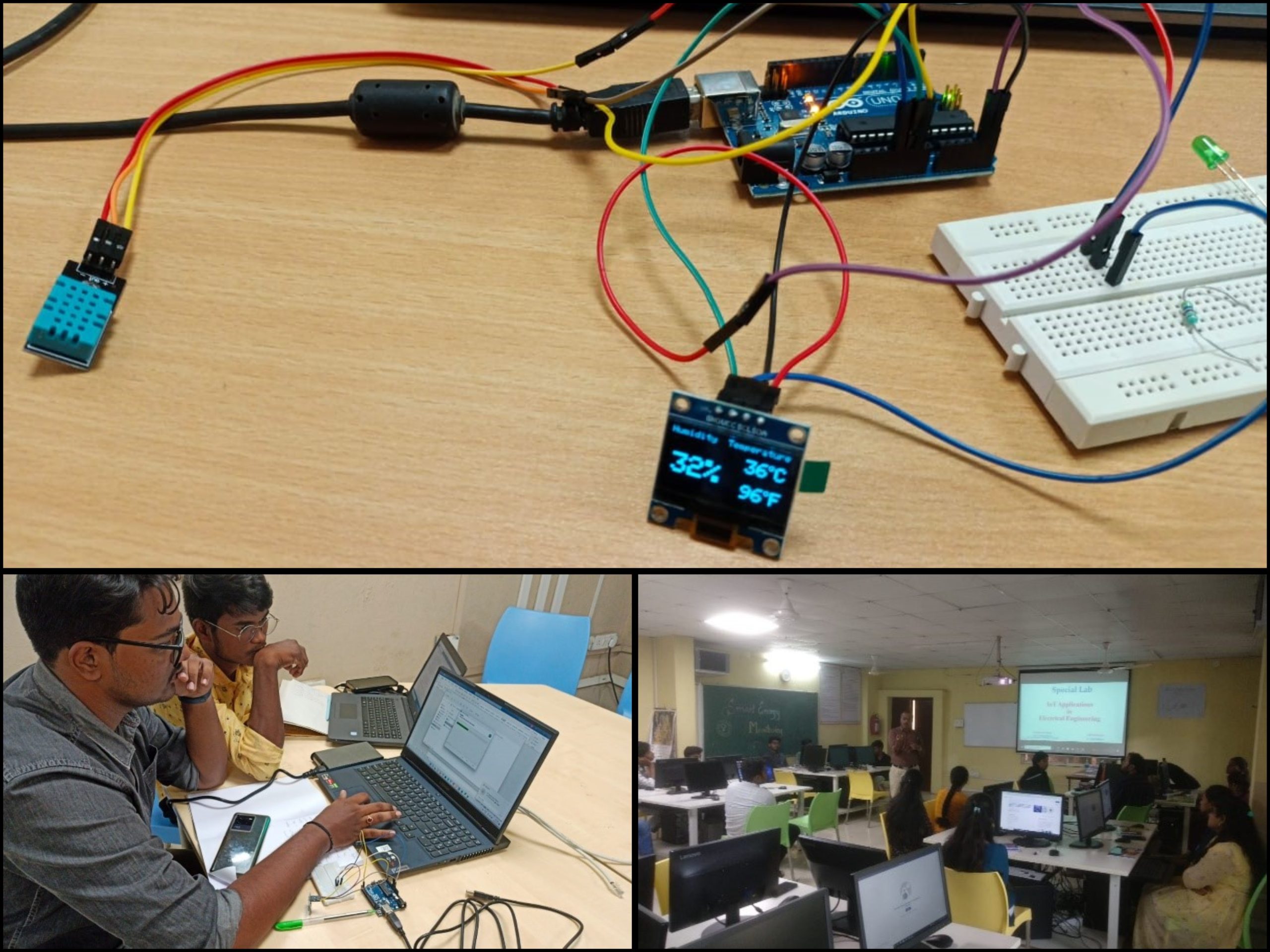

Understand the IoT using Arduino programming, Explain the interfacing of data, I/O devices with Arduino UNO, Interfacing of different sensors with Arduino UNO, ESP32 Interfacing of different motors like DC Motor, Servo motor with Arduino UNO, ESP32.

In the realm of sensors, students delve into the principles of temperature sensing for climate control and industrial applications, understand humidity sensing for environmental monitoring and HVAC systems, and explore gas concentration measurement for safety and pollution detection. Displays like OLED and LCD are incorporated for visual representation, crucial in IoT projects presenting real-time data and user interfaces.

The lab extends its focus to motor control systems, exposing students to different motors and their integration with microcontrollers. Understanding the significance of motor drivers for efficient control and energy management is a key facet. Additionally, students explore relay modules for controlling high-power electrical devices, simulating applications in home automation and industrial processes.

Objectives:

- To form a bridge between the industry and academic institutions to update their knowledge.

- To understand the need of IoT in the research community software industry in India.

- To Appreciate differences between Big Data, cloud computing and IoT.

- To understand the innovative application’s needs such as smart city, smart health, smart manufacturing, Smart agriculture, etc..

- To train in designing and programming the IoT based System.

- To build industry capable talent, start-up community and entrepreneurial ecosystem for IoT.

- To understand the reduction of import dependency on IoT components and promote the action.

- To energize research mind-set and reduce costs in research and development by providing neutral and interoperable, multi-technology stack laboratory facilities.

- To provide environment for product creation, testing and also validation & incubation.

Components:

- Arduino Uno, Node MCU, ESP 32

- Different types of sensors

- Relay Modules

- LCD Display and OLED

- Different types of motor with driver circuit

Outcomes:

- Understand the basic applications areas of IoT.

- Able to realize the revolution in Mobile devices, Cloud & Sensor networks, software agents.

- Understand design methodology and hardware platforms involved in IoT.

- Students will be able to design and apply effective techniques to create IoT based applications under in-house expert guidance.

- Students will become more industry ready, Technology gap between Industry and Institute will be reduced.

- Understand how to analyse and organize the data.

- Cloud connected IoT platform creates solutions that enable you to develop, deploy, manage IoT connected devices.

- IoT solutions enable near real time response and the ability to work in offline/intermittent connectivity to the applications in Industrial environments.

About:

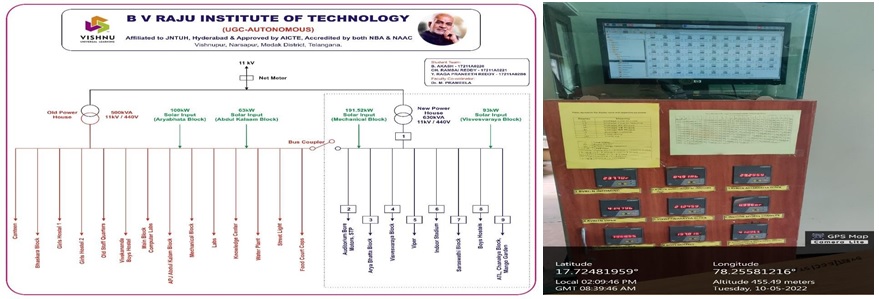

Data analytics on the electrical parameters is needed in order to improve energy consumption efficiency and prevent adverse events such as power outage, short circuit etc.,. It also helps in protecting and increase the longevity of the electrical equipment. The electrical consumption data is measured usually using the multifunction meter(MFM) installed in residential or commercial buildings. In the commercial buildings, these meters are installed in the panel room (centralized) and in all floors/de- (decentralized). The extraction of data is the first step for the process of data analytics. In order to demonstrate the data retrieval process, a hardware lab set up is implemented using RS 485 communication interfaced multifunction meter (MFM). In addition to the MFM, certain modules (both hardware and software) used for the data extraction.

Objectives:

- Visualization of campus-network with real-time data

- Parameters to be monitored: Voltages (R, Y, B), Voltages (RY, YB, BR), currents (R, Y, B), Frequency,active power, reactive power, apparent power of all phases, power factor of all phases, energy consumption in KWH,using, IITH indigenously developed IoT module, Modbus RTU, class 0.2s & 1, computer server, large display unit for SCADA display of the network.

- Energy consumption alerting on vulnerabilities and reporting.

- Open Data platform for students for performing various energy data analytics and projects on machine learning (ML), artificial intelligence (AI) applications in smart

- Data collection and analysis of power distribution and eradication of unforeseen power shut off.

Outcomes:

- Website for monitoring the campus energy (intranet).

- Web based SCADA like display of single line diagram of entire campus.

- Further displays of realtime and historical data at each monitoring point.

- Plots of voltage, current, power of each metering point.

- Daily Energy Consumption reports.

- Meter-wise, block-wise.

- Weekly Energy Consumption.

- Monthly Energy Consumption reports.

- Email alerts:

- Daily, weekly and monthly.

- Over and Under voltage alerts.

- Power interruption report.

- Alert on the crossing of 80% of contracted maximum demand.

The following projects can be executed using the above hardware and software system

- Energy consumption analysis

- Data Analysis on Energy Monitoring Data

- Data driven management for Energy savings

- Campus Energy data Analytics

- Energy Data Analytics on BVRIT campus

- Energy data analysis

- Data driven Energy consumption analysis

- Data driven Energy consumption analysis for Reducing Tariff

- Data driven load scheduling

Vision:

To combine four different technologies, namely a wind solar hybrid system, a submersible motor pumping system, a street light system, and a drip irrigation system, into a full solution for a horticulture farmer, therefore benefiting both the farmer and society as a whole.

Objectives:

- 365 days uninterrupted, high-quality power.

- Power that is clean and does not pollute the environment.

- Agriculture labour expenses are reduced.

- No motors will be burned by low-quality electricity caused by voltage fluctuations.

- Saves 25% of the water needed for irrigation.

- Produces a 25% to 50% increase in crop output.

- Reduce global warming, conserve water, and boost horticultural crop yields.

Description:

The photovoltaic array consists of two 30V 8A panels interconnected in parallel. The planned photovoltaic system has a total capacity of 480W. The photovoltaic effect turns solar energy into electric energy, yielding DC voltage as a result. The output DC voltage is generated by a wind turbine with a total capacity of 700W and an average speed of 5m/s. The fundamental benefit of hybrid solar energy is that it collects energy from both solar and wind sources, using PV panels for solar energy and wind turbines for wind energy. Using the photovoltaic principle, a solar panel receives the sun’s rays and converts them into DC electricity. And also the wind turbine revolves owing to the force of the wind, and its rotor is connected to a generator, which simultaneously rotates and produces AC electricity.

Components:

- Wind mill,

- Solar panels,

- Charge controller,

- Auto Grid change over,

- Timer,

- Lead acid Batteries of 150 Ah,

- Inverter,

- Water pump and

- Lighting load.

Specifications:

CAPACITY: 1180 WATTS

WIND SYSTEM: 700WATTS, 23 A, 30 V.

PV SYSTEM: 480 WATTS, 16 A, 30 V.

SOLAR PANELS: Number of Panels-2, EACH RATING 30V, 8A, 240W.

Research Area:

- To analyze the load of Solar Wind Power Generation System with different loads.

- To analyze the power generation of Solar Wind Power Generation System from environmental conditions.

- To analyze the load of Solar Wind Power Generation System for different seasons.

- Experimental Load Analysis of Hybrid Solar Wind Power Generation System in Comparison with MATLAB/SIMULINK.

- Designing a multistage submersible motor that runs on the 850W clean power generated by WSHS unit.

- Designing automated electronic circuits for battery charge controller.

- Designing automated timer circuits to switch on and off the water supply to drip pipes by maintaining a pre-set pressure in the pipes.