1. Civil Engineering Software Laboratory

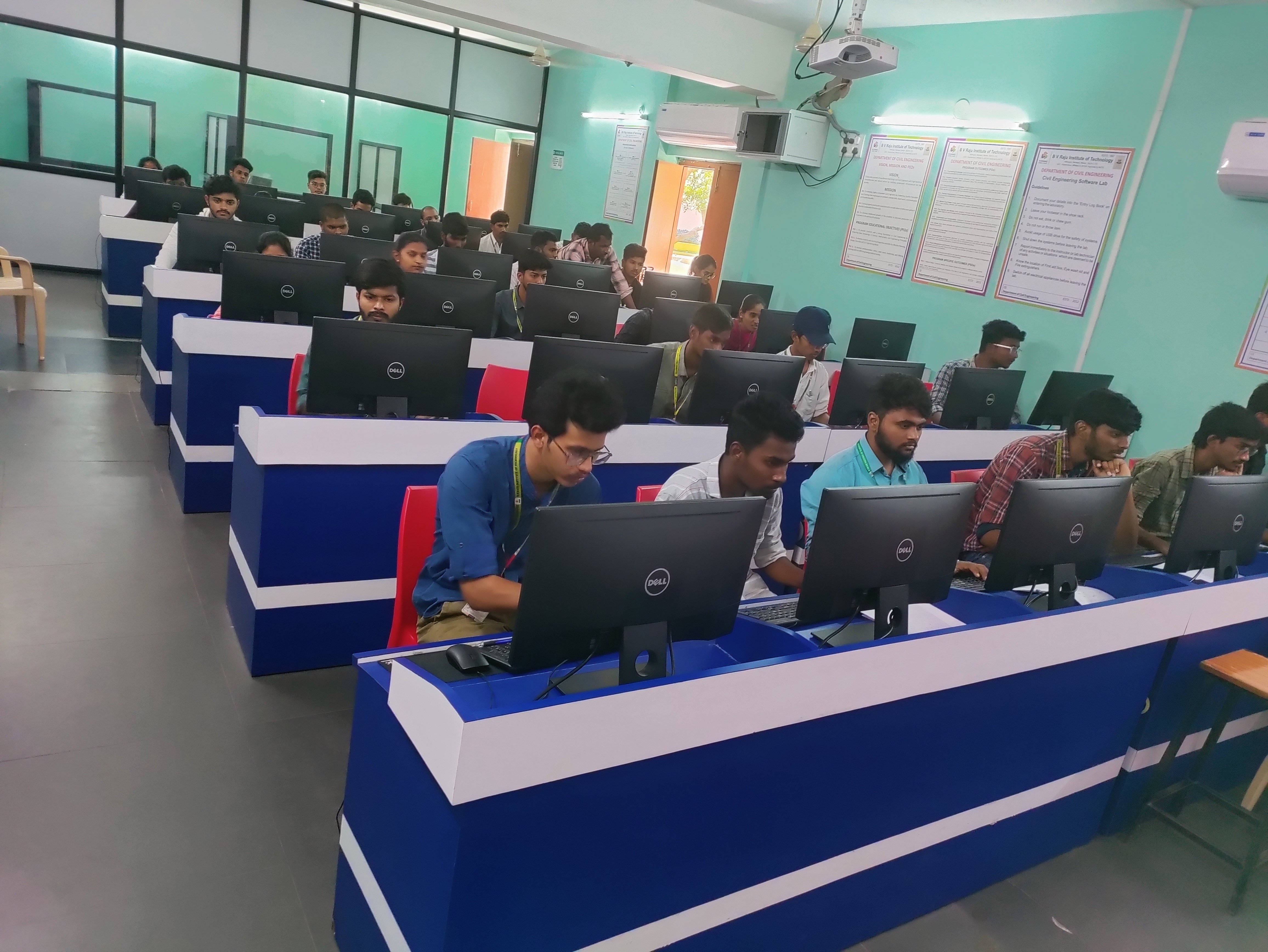

The Civil Engineering Software Laboratory is established to enhance the academic, research, and professional competencies of students and faculty across various domains of civil engineering. The lab is equipped with industry-standard software tools, including Autodesk’s educational suite (AutoCAD and Revit) and Bentley Systems academic perpetual offerings (STAAD.Pro, OpenRoads Designer, WaterGEMS, and SewerGEMS), enabling advanced capabilities in design, analysis, and Building Information Modeling (BIM). Additionally, the lab supports the use of open-source and industry-relevant platforms such as QGIS and Oracle Primavera P6, promoting accessible and flexible learning opportunities.

The Civil Engineering software lab spread across an area of 132 sq.m, the lab is functionally divided into an academic lab and an advanced skill development lab, both furnished with high-end workstations and networking infrastructure. This facility offers hands-on training, cultivates industry-ready software skills, supports research in computational modeling and infrastructure planning, and prepares students for professional certifications and placements. Overall, the lab plays a crucial role in integrating modern technology with civil engineering education, providing students with practical exposure aligned with current industry standards.

As per the R22 Regulations, The Civil Engineering Software lab caters to multiple specialized laboratory courses across the B.Tech curriculum, providing practical exposure to software tools used in planning, modeling, design, and construction management. The lab supports the following courses:

• B.Tech II Year II Sem: Computer Aided Building Planning and Drawing Lab

• B.Tech III Year II Sem: (BIM) Building Information Modelling Lab

• B.Tech IV Year I Sem: 1. Computer Aided Design of Structures Lab

2. Construction Management Tools Lab

2. Surveying and Geomatics Laboratory

The Surveying & Geomatics Laboratory is designed to enhance the academic, research, and professional competencies of students and faculty in geospatial aspects of civil engineering. The lab is equipped with modern surveying instruments such as the Differential Global Positioning System (DGPS), Total Station, Auto Level, and Theodolite, enabling precise data acquisition, field measurements, and spatial analysis.

Covering an area of 25 sq.m, the lab is functionally divided into an academic section and an advanced fieldwork section. Both are furnished with appropriate infrastructure to support hands-on training in topographic and engineering surveying. The facility fosters a practical learning environment where students can apply surveying principles in real-world scenarios, enhancing their skills in error correction, mapping, and geodetic computations.

The laboratory plays a crucial role in integrating modern surveying technology into civil engineering education. Through direct exposure to advanced equipment and field procedures, students gain a comprehensive understanding of traditional and contemporary surveying techniques. The lab also emphasizes the importance of data integration with Geographic Information Systems (GIS), promoting interdisciplinary learning and research.

As per the R22 Regulations, the Surveying & Geomatics Lab supports core laboratory courses within the B.Tech Civil Engineering program. It specifically caters to:

B.Tech II Year I Semester: Surveying and Geomatics Lab

3. Concrete Technology Laboratory

The Concrete Technology and Highway Materials Laboratory is designed to enhance the academic, research, and professional competencies of students and faculty in the material science and pavement engineering aspects of civil engineering. The lab is equipped with modern testing instruments such as the Ultrasonic Pulse Velocity (USPV) apparatus, Digital Rebound Hammer, and Pavement Grinding Machine, enabling precise assessment of concrete quality, in‑situ strength evaluation, and pavement surface analysis.

Covering an area of 25 sq.m, the lab is functionally divided into an academic testing section and an advanced pavement evaluation section. Both zones are furnished with specialized benches, safety equipment, and data‑acquisition systems to support hands‑on training in concrete mix design, non‑destructive testing, and surface profile measurements. This dual‑section layout fosters a practical learning environment where students apply concrete technology principles and pavement diagnostics in real‑world scenarios, sharpening their skills in material characterization, quality control, and distresses quantification.

The laboratory plays a crucial role in integrating modern materials‑testing technology into civil engineering education. Through direct exposure to non‑destructive evaluation tools and pavement maintenance machinery, students gain a comprehensive understanding of both traditional strength‑testing methods and contemporary surface performance assessments. The lab also emphasizes the importance of correlating test data with durability models and life‑cycle analysis, promoting interdisciplinary learning across structural, materials, and transportation engineering.

As per the R22 Regulations, the Concrete Technology and Highway Materials Lab supports core laboratory courses within the B.Tech Civil Engineering program. It specifically caters to:

B.Tech III Year II Semester: Concrete Technology and Highway Materials Lab

4. Geotechnical Engineering Laboratory

The Geotechnical Engineering Laboratory is designed to enhance the academic, research, and professional competencies of students and faculty in the field of soil mechanics and foundation engineering. The lab is equipped with modern testing instruments such as the Plate Load Test apparatus, Unconfined Compression Testing Machine, and California Bearing Ratio (CBR) testing setup, enabling detailed assessment of soil strength, bearing capacity, and subgrade performance.

Covering an area of 25 sq.m, the lab is functionally divided into a basic soil testing section and an advanced foundation evaluation section. Both sections are equipped with test pits, reaction frames, loading plates, and safety accessories to support hands‑on training in soil classification, compaction, strength evaluation, and pavement subgrade analysis. This functional division offers a practical learning environment where students apply geotechnical engineering principles to real‑world applications such as bearing capacity assessment, shallow foundation design, and pavement layer evaluation.

The laboratory plays a crucial role in integrating soil behavior and foundation testing into civil engineering education. Through direct engagement with field-oriented equipment and laboratory test setups, students gain a thorough understanding of both traditional soil mechanics and applied geotechnical investigations. The lab also emphasizes the interpretation of field and lab test results to support empirical design methods, performance predictions, and soil-structure interaction studies, encouraging interdisciplinary insights across structural and transportation domains.

As per the R22 Regulations, the Geotechnical Engineering Lab supports core laboratory courses within the B.Tech Civil Engineering program. It specifically caters to:

B.Tech III Year I Semester: Geotechnical Engineering Lab

5. Environmental Engineering Laboratory

The Environmental Engineering Laboratory is designed to enhance the academic, research, and professional competencies of students and faculty in the domains of water quality assessment and environmental monitoring. The lab is equipped with essential analytical instruments such as the Water Quality Analyzer, Conductivity Meter, and Titration Apparatus, facilitating accurate determination of physico‑chemical parameters in water and wastewater samples.

Covering an area of 25 sq.m, the lab is functionally divided into a water analysis section and a chemical testing section. Both zones are furnished with reagent storage units, safety facilities, and sample preparation setups to support hands‑on training in water quality testing, pollution load estimation, and chemical dosage studies. This dual‑section layout provides a practical learning environment where students apply environmental engineering principles in real‑time water quality monitoring and treatment studies.

The laboratory plays a vital role in integrating environmental analysis and sustainability concepts into civil engineering education. Through direct exposure to standard testing procedures and analytical instrumentation, students gain a comprehensive understanding of environmental regulations, contaminant characterization, and water treatment strategies. The lab also emphasizes the correlation of test results with environmental standards and pollution control frameworks, fostering interdisciplinary learning across water resources, public health, and sustainable engineering practices.

As per the R22 Regulations, the Environmental Engineering Lab supports core laboratory courses within the B.Tech Civil Engineering program. It specifically caters to:

B.Tech III Year II Semester: Environmental Engineering Lab

6. Strength of Materials Laboratory

The Strength of Materials Laboratory is designed to enhance the academic, research, and practical understanding of material behavior under various loading conditions, serving both students and faculty in the field of structural and material engineering. The lab is equipped with advanced testing instruments such as the Universal Testing Machine (UTM), Impact Testing Machine, Torsion Testing Machine, and Hardness Testing Machine, enabling precise evaluation of mechanical properties like strength, toughness, stiffness, and hardness.

Covering an area of 25 sq.m, the lab is functionally organized into a tensile and compressive testing section and a dynamic and hardness evaluation section. These sections are equipped with test benches, digital indicators, safety systems, and specimen preparation tools to facilitate hands‑on training in fundamental strength tests, including tension, compression, shear, impact, torsion, and hardness assessments. This layout ensures a practical learning environment where students can directly observe the stress-strain behavior of materials and understand failure mechanisms.

The laboratory plays a fundamental role in bridging theoretical mechanics with real-world material response under loads. Through direct experimentation and observation, students gain deep insights into material performance, design safety margins, and structural reliability. The lab also emphasizes data interpretation, comparison with standard codes, and integration with design calculations, promoting interdisciplinary learning across structural analysis, materials science, and mechanical design.

As per the R22 Regulations, the Strength of Materials Lab supports core laboratory courses within the B.Tech Civil Engineering program. It specifically caters to:

B.Tech II Year I Semester: Strength of Materials Lab

7. Fluid Mechanics and Hydraulic Machinery Laboratory

The Fluid Mechanics and Hydraulic Machinery Laboratory is designed to enhance the academic, research, and practical understanding of fluid behavior and hydraulic systems, supporting students and faculty in the fields of hydraulics and water resources engineering. The lab is equipped with specialized equipment such as the Impact of Jet on Vanes apparatus, Pelton Wheel Turbine, Kaplan Turbine, Francis Turbine, and Open Channel Flow setups, enabling comprehensive analysis of fluid properties and performance of hydraulic machines.

Covering an area of 25 sq.m, the lab is functionally divided into a fluid mechanics testing section and a hydraulic machinery section. Both sections are outfitted with flow measurement units, control valves, pressure gauges, and safety systems to facilitate hands‑on training in flow visualization, energy conversions, and turbine efficiency studies. This dual‑zone layout provides a dynamic environment for students to observe and analyze key hydraulic phenomena in real-time conditions.

The laboratory plays a vital role in integrating theoretical fluid mechanics with practical hydraulic applications in civil engineering. Through experimental investigations and machine testing, students gain a strong foundation in fluid flow behavior, turbine operation, and energy losses in channels and pipes. The lab also emphasizes the comparison of experimental data with theoretical predictions and design curves, encouraging interdisciplinary learning across water resources, mechanical systems, and sustainable infrastructure planning.

As per the R22 Regulations, the Fluid Mechanics and Hydraulic Machinery Lab supports core laboratory courses within the B.Tech Civil Engineering program. It specifically caters to:

B.Tech II Year II Semester: Fluid Mechanics and Hydraulic Machinery Lab